I Am Telling This Because Many Important Points I Have Covered During Making Of Video, So If You Want To Know In Detail Then Watch My Video On YouTube Which is Given Below. International Congress ‘Creating with Concrete’, University of Dundee, UK, September 6-10, 1999. ‘Influence of Chemical Admixtures and Mixing on the Mix Proportion of General Purpose Self-Compacting Concrete’. 8 K Takada, G I Pelova and J C W Walraven. Concrete Library of JSCE, no 25, June 1995, pp 107-120. EHS Grout Calculator spreadsheet using the Calcs - Nested Well worksheet. ‘Mix Design for Self-Compacting Concrete’. If You Want Detailed Knowledge Then Watch My Video On YouTube Channel: Civil Learning Technology. 10-gallon pail - used to mix Portland cement and water to make neat cement. Q8.What is the Coarse aggregate size preferable for Self Compacting Concrete?Īnswer: The Coarse aggregate size preferable for Self Compacting Concrete is 10 mm to 12mm.

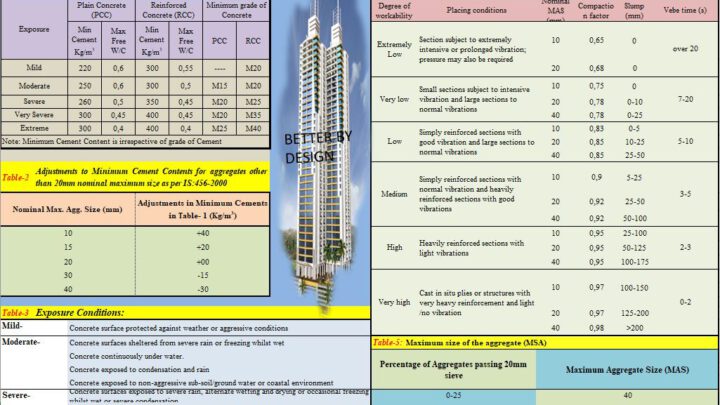

What is the limitation of height difference for the pouring of Concrete for the RCC column?Īnswer: The limitation of the height difference for the pouring of Concrete for the RCC column is 500 mm. The above tests shall be carried out as per IS 1199 (Part 6). What are the main features of Fresh Self Compacting Concrete?Īnswer: As per IS 10262: 2019 Clause-7.2, A concrete mix can only be classified as self-compacting concrete, if the requirements for all below-mentioned characteristics are fulfilled: What is the Maximum and Minimum limitation of water for Self Compacting Concrete?Īnswer: As per IS 10262: 2019 Clause-8.3 (b), the Maximum and Minimum limitation of water for Self Compacting Concrete is from 150 to 210 kg/m 3 Q4.What is the amount of Fines preferable for Self Compacting Concrete?Īnswer: As per IS 10262: 2019 Clause-8.3 (a), Sufficient amount of fines (< 0.125 mm) preferably in the range of 400 kg/m3 to 600 kg/m3, inclusive of suitable quantities of fine aggregate and mineral admixtures like fly ash in suitable proportions, may be used for flowability while ensuring compliance with engineering properties particularly shrinkage. What is the desirable size of Fines for Self Compacting Concrete?Īnswer: As per IS 10262: 2019 Clause-8.3 (a), the desirable size of Fines for Self Compacting Concrete is 0.125 mm or 125 Micron. How much water reduction is possible with Polu Carboxylate Ethers (PCE)?Īnswer: As per IS 10262: 2019 Clause-8.3 (c), Use of high range water reducing admixture like polycarboxylate ether-based high range water reducing admixture (water reduction > 30 percent) and sometimes also using a viscosity modifying admixture (VMA) in appropriate dosages. SCC's stability, or resistance to segregation of the plastic concrete mixture, is achieved by using mineral fillers or fines and/or by using viscosity modifying admixtures.Q2. SCC's flowability is generally achieved by using polycarboxylate-based high-range water-reducing (HRWR) admixtures and optimized concrete ingredients while maintaining a low mixing water content in the concrete. SCC: A high-performance concrete innovation. If the SCC mixture is designed to have a higher paste content or fines compared to conventional concrete, an increase in shrinkage may occur. SCC mixtures can be designed to provide the required hardened concrete properties for an application, similar to regular concrete. SCC mixtures typically have a higher paste volume, less coarse aggregate, and higher sand-to-coarse aggregate ratio than typical concrete mixtures. Control of aggregate moisture content is also critical to producing a good mixture. While SCC mixtures have been successfully produced with 1 ½ inch (38 mm) aggregate, it is easier to design and control with smaller-sized aggregate. A well distributed aggregate grading helps achieve SCC with reduced cementitious materials content and/or reduced admixture dosage.

Self compacting concrete mix design excel sheet software#

software engineer - IMC Financial Markets The Her Campus Integrated Marketing Internship is open to. Increased fines contents can be achieved by increasing the content of cementititious materials or by incorporating mineral fines.Īdmixtures that affect the viscosity of the mixture are especially helpful when the grading of available aggregate sources cannot be optimized for cohesive mixtures or with large source variations. Youd rather not bore yourself with university life. The stability or resistance to segregation of the plastic concrete mixture is attained by increasing the total quantity of fines in the concrete and/or by using admixtures that modify the viscosity of the mixture.

The high flowability of SCC is generally attained by using high-range water-reducing (HRWR) admixtures and not by adding extra mixing water. Two important properties specific to SCC in its plastic state are its flowability and stability.

Properly designed SCC can save time and labor without sacrificing performance. Traditionally, concrete with the fluidity of SCC has had a very high water-to-cement ratio, which would lower compressive strengths and compromise durability. Concrete producers must “retrain their eyes” for this very fluid mixture as it turns corners and fills forms. SCC looks very different from conventional concrete while mixing.

0 kommentar(er)

0 kommentar(er)